Building stones are essential materials in construction, and their properties significantly influence the durability and strength of structures. To ensure that stones meet the required standards for various construction applications, a series of tests are conducted to evaluate their physical and chemical properties. This article explores the different tests performed on building stones, highlighting their significance and methodologies.

Importance of Testing Building Stones

Testing building stones is crucial for assessing their suitability for specific construction projects. These tests provide valuable insights into the stones’ physical characteristics, such as strength, hardness, and resistance to weathering. Understanding these properties helps engineers and architects make informed decisions when selecting materials, ultimately ensuring the longevity and safety of structures.

Types of Tests on Building Stones

Acid Test

The acid test determines the presence of calcium carbonate in building stones, which can negatively impact their weathering quality. In this test, a sample weighing between 50 to 100 grams is immersed in a one percent solution of hydrochloric acid for seven days. The solution is agitated periodically. A good building stone will maintain its sharp edges and remain free of powder. In contrast, if the edges break and powder forms, it indicates a high calcium carbonate content, suggesting poor weathering quality. This test is commonly conducted on sandstones.

Attrition Test

The attrition test assesses the wear resistance of stones used in road construction. The procedure involves breaking stones into 60mm pieces, weighing 5 kg, and placing them in a Devil’s attrition test machine. The cylinders of the machine, which are closed and inclined at a 30-degree angle, rotate for five hours at 30 revolutions per minute (rpm). Afterward, the contents are sieved through a 1.5mm mesh, and the percentage of wear is calculated using the formula:

[ \text{Percentage wear} = \left( \frac{\text{Loss in Weight}}{\text{Initial Weight}} \right) \times 100 ]

Crushing Test

To evaluate the compressive strength of building stones, the crushing test is performed. Samples are cut into cubes measuring 40 x 40 x 40 mm, which are then saturated in water for 72 hours. Prior to testing, the load-bearing surface of the cube is covered with 5mm thick plaster of Paris. The load is applied axially in a crushing test machine at a rate of 140 kg/sq.cm per minute. The crushing strength is determined by dividing the maximum load at which the sample fails by the area of the bearing face.

Crystalline Test

The crystalline test evaluates the potential decay of stone due to crystallization effects. Four cubes of stone, each with a side of 40 mm, are dried and weighed before being immersed in a 14% sodium sulfate solution for two hours. After drying at 100 degrees Celsius, the cubes are weighed again. This process is repeated multiple times, with weight changes noted and expressed as a percentage of the original weight. The test highlights how crystallization of calcium sulfate in stone pores can lead to deterioration.

Freezing and Thawing Test

This test examines a stone’s resilience to freeze-thaw cycles, which can cause cracking and structural failure. A stone specimen is immersed in water for 24 hours, then frozen at -12 degrees Celsius for 24 hours. The stone is thawed at atmospheric temperature, and the procedure is repeated several times. The behavior of the stone is closely observed to assess its durability under these conditions.

Hardness Test

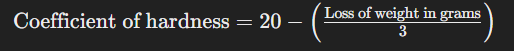

To determine the hardness of a stone, a hardness test is conducted using Dorry’s testing machine. A cylindrical sample of stone is weighed and placed in the machine, subjected to a pressure of 1250 grams. During the rotation of the machine at 28 rpm, coarse sand is sprinkled on the disc. After 1000 revolutions, the specimen is removed and weighed again. The coefficient of hardness is calculated using the formula:

Impact Test

The impact test measures the toughness of stones. A cylindrical specimen is placed on a cast iron anvil, and a 2 kg steel hammer is dropped axially onto it. The height of the first blow is 1 cm, with subsequent blows increasing in height (2 cm, 3 cm, etc.). The blow at which the specimen breaks is noted, and this value represents the toughness index of the stone.

Microscopic Test

Microscopic examinations of stone samples allow for an in-depth analysis of their properties. Sections of stones are observed under a microscope to study various characteristics, including average grain size, existence of pores, fissures, mineral constituents, nature of cementing material, presence of harmful substances, and overall texture.

Smith’s Test

Smith’s test is performed to determine the presence of soluble matter in a stone sample. Small chips of the stone are placed in a glass tube filled with clear water. After one hour, the tube is shaken vigorously. If earthy matter is present, the water will turn dirty; if it remains clear, the stone is considered durable and free from soluble matter.

Water Absorption Test

The water absorption test assesses the porosity and absorption characteristics of stones. A cube of stone weighing about 50 grams is prepared and its weight recorded (W1). After being immersed in distilled water for 24 hours, the cube is weighed again (W2). The cube is then suspended in water to record its weight (W3) and boiled for five hours, followed by another weighing (W4). Various properties, including percentage absorption, volume of displaced water, porosity, density, and specific gravity, are calculated using the recorded weights.

Conclusion

The various tests conducted on building stones are essential for determining their quality and suitability for construction. These tests provide crucial information about the stones’ physical and chemical properties, ensuring that only the best materials are used in construction projects. By understanding the results of these tests, engineers and architects can make informed decisions that enhance the durability and safety of structures, ultimately contributing to successful construction practices.