Rocks play a vital role in construction and engineering, serving as foundational materials in infrastructure, tunnels, and various structural projects. However, not all rocks possess the same properties, and their suitability for engineering applications varies. Due to differences in strength, structure, and stability, engineers require a systematic approach to classify rocks, especially for demanding projects. In 1974, Z.T. Bieniawski introduced the Geomechanics Classification System, commonly known as the Rock Mass Rating (RMR) system, which provides a comprehensive method for evaluating the quality of rock masses based on specific engineering-related parameters.

The RMR system assigns a value from 0 to 100 to a rock mass, where higher values indicate better rock quality. This classification aids engineers in determining the suitability of rocks for various applications. The RMR value is derived from six key parameters, each of which impacts the rock’s behavior and stability in engineering contexts.

1. Rock Mass Rating (RMR) System

The RMR system’s main advantage is its ability to quantify rock quality, making it a valuable tool for engineers. The rating is based on six parameters:

- Strength of the rock

- Drill core quality

- Joint spacing

- Joint characteristics

- Groundwater conditions

- Orientation of joints

Each parameter has a designated influence on the RMR, and when combined, these factors yield an RMR value that reflects the overall quality and stability of the rock mass.

2. Key Properties of Rocks for Engineering

Each of the six parameters plays a specific role in determining the RMR and the rock’s overall suitability for engineering.

A. Compressive Strength of Rock

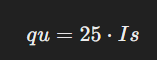

The compressive strength of rock is a critical factor in RMR assessment. This strength is typically measured through laboratory compression tests on prepared specimens or point load tests on drill core samples. The compressive strength, denoted as ( qu ), is calculated using the point load strength ( Is ) with the formula:

Rocks with higher compressive strengths receive higher RMR increments, with values ranging from 15 for very strong rocks to 0 for rocks with minimal compressive strength. Rocks with RMR increments less than 3 are generally deemed unsuitable for engineering purposes.

B. Drill Core Quality

Drill core quality is evaluated using the Rock Quality Designation (RQD), which is expressed as a percentage based on the recovered length of core samples. The RQD provides insight into the rock’s intactness, with higher RQD percentages indicating better quality. For example, an RQD above 90% receives an RMR increment of 20, while an RQD below 25% only receives 3 points. This classification helps engineers assess the continuity of the rock and its potential stability in applications.

C. Joint Spacing

Joint spacing significantly impacts the rock mass rating. Rocks with wider joint spacing tend to have greater stability, making them more favorable for engineering projects. RMR increments range from 30 for rocks with joint spacing over 3 meters, down to 5 for those with extremely close spacing (less than 0.005 meters). The presence of fewer joints or widely spaced joints often improves the rock’s strength, which is reflected in a higher RMR score.

D. Joint Characteristics

The characteristics of joints, including their roughness, aperture, and wall rock hardness, influence the RMR increment for this parameter. Joints with very rough surfaces and hard wall rock are rated the highest, with an RMR increment of 25. Conversely, open joints with substantial filling and extensive length receive no points. This aspect of the RMR system highlights the importance of joint condition in determining the rock’s ability to handle structural loads and stresses.

E. Groundwater Conditions

Groundwater significantly affects rock mass stability, as water pressure and moisture can lead to structural weakening. The RMR system categorizes groundwater conditions, ranging from completely dry to conditions with severe water problems. Rocks in dry environments receive an RMR increment of 10, while those under severe water stress receive only 0 points. This parameter ensures that the rock’s interaction with groundwater is factored into its suitability for engineering applications.

F. Orientation of Joints

The orientation of joints is a vital parameter, especially for projects involving tunneling, mining, and foundation construction. Depending on the alignment of joints with respect to the engineering work, the rock mass rating is adjusted. In cases where joint orientation is very favorable, no points are deducted. However, unfavorable orientations can lead to deductions, with adjustments ranging from 0 to -12 for tunneling projects and 0 to -25 for foundation work. This parameter emphasizes the importance of alignment between joint orientation and engineering needs for stability.

Conclusion

The Rock Mass Rating (RMR) system is a crucial tool in engineering, providing a systematic approach to evaluate rock suitability. By assessing six key parameters, engineers can gauge the quality, strength, and stability of rock masses for specific applications. This classification system allows for informed decisions in selecting the appropriate type of rock for construction, tunneling, mining, and other projects requiring structural integrity.

The RMR system offers engineers a standardized way to ensure that the chosen rock mass aligns with the demands of the project, promoting safety, reliability, and efficiency in engineering practices.