In modern construction, the demand for efficient, cost-effective, and structurally sound building materials is at an all-time high. One such material that has gained popularity in recent years is lightweight concrete. Known for its superior strength-to-weight ratio, lightweight concrete offers a variety of benefits, particularly in floor systems, where it can reduce material costs and structural load while maintaining performance and safety standards. This article explores the features, types, applications, and economic advantages of lightweight concrete floors.

The Advantage of Lightweight Concrete

Lightweight concrete floors are increasingly being used in a wide range of construction projects due to their excellent strength-to-weight ratio. By reducing the quantity of concrete and steel reinforcement required, lightweight concrete systems help offset the marginally higher initial costs compared to traditional concrete systems. The overall reduction in weight contributes significantly to structural efficiency, making it a preferred choice in multi-story buildings and structures that require high load-bearing capacity without compromising on material costs.

The primary motivation for using lightweight concrete floors is the reduction of dead loads on the structure. This reduction lowers the overall weight of the building, which, in turn, minimizes the size of foundations and supporting structures, leading to significant cost savings over the life of the project.

Types of Lightweight Concrete

Lightweight concrete comes in several forms, each with its own properties and applications. The most common types of lightweight concrete include:

1. Lightweight Aggregate Concrete

This type of lightweight concrete is produced by replacing traditional coarse aggregates with lightweight aggregates, such as expanded clay, shale, or pumice. These aggregates reduce the overall density of the concrete without compromising its strength, making it ideal for structural applications that require reduced weight. The production process for lightweight aggregate concrete is similar to conventional concrete, ensuring familiarity for engineers and contractors.

2. Foam Lightweight Concrete

Foam concrete contains air bubbles generated through a foaming agent, which reduces its density. Despite its low weight, foam concrete offers excellent mechanical strength and thermal insulation properties, making it ideal for use in filling and levelling layers of floors in industrial buildings and other civic structures. Its ability to provide substantial weight reduction without sacrificing strength makes it a versatile material for floor systems.

3. Polystyrene Lightweight Concrete

Polystyrene lightweight concrete has a similar density and thermal conductivity to foam concrete but with enhanced insulation properties. It is particularly suitable for constructing thermal insulating layers, often used in the construction of flat roofs, where both insulation and structural efficiency are crucial. Polystyrene-based concrete offers a cost-effective solution for creating gradient layers while maintaining excellent mechanical properties.

Types of Lightweight Concrete Floor Systems

Lightweight concrete floors can be designed using various systems depending on the specific requirements of the project. These systems are divided into three main categories:

1. Solid Lightweight Concrete Floors

Solid lightweight concrete floors are typically constructed by pouring lightweight aggregate concrete into fixed forms. This system is often used in multi-story buildings, where the floor system must support considerable loads while minimizing structural weight. The thickness of these floors is carefully determined according to specifications outlined in the American Concrete Institute (ACI 318-14), ensuring they meet the necessary strength and durability standards.

Solid lightweight floors are ideal for reducing the overall weight of a building, particularly in high-rise constructions where reducing dead loads can contribute to overall cost savings in the foundation and support structures.

2. Composite Lightweight Concrete Floors

Composite lightweight concrete floors consist of profiled steel decking combined with an in-situ reinforced concrete topping. The steel decking acts as a permanent formwork and provides a shear bond with the concrete, enhancing the structural integrity of the floor system. This type of floor system is common in commercial and industrial buildings, where long spans and high load-bearing capacity are required.

One of the primary advantages of composite lightweight floors is their ability to support greater spans while using fewer structural supports (such as columns), leading to more open, flexible spaces inside buildings. The profiled steel decking can be in various shapes, including re-entrant and trapezoidal profiles, offering versatility in design and functionality.

3. Other Lightweight Concrete Floor Systems

In addition to solid and composite lightweight concrete floors, there are several other innovative floor systems that use lightweight concrete materials. These include:

- Lightweight Wood Concrete Slab: A hybrid system that combines lightweight concrete with wood elements, providing a sustainable and cost-effective flooring solution.

- Modular Lightweight Concrete Floor System: Pre-engineered and prefabricated panels made of lightweight concrete that can be easily assembled on-site, reducing construction time and labor costs.

- Precast Concrete Lightweight Concrete Floor: Precast panels made from lightweight concrete, ideal for large-scale commercial projects where speed and cost efficiency are important.

Determining the Minimum Thickness of Lightweight Concrete Floors

The thickness of a lightweight concrete floor is an important consideration to ensure the structural integrity of the building while meeting design specifications. According to the ACI 318-14 standards, the minimum thickness for lightweight concrete floors is calculated based on the structural requirements and load-bearing capacity of the system.

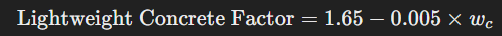

To calculate the minimum thickness of a slab, the lightweight concrete factor is used, which adjusts the general thickness guidelines for normal-weight concrete. The lightweight concrete factor is determined using the formula:

Where ( wc ) is the weight of the lightweight concrete (measured in KN/m³). By factoring in the specific weight of the lightweight concrete used in a particular floor system, engineers can determine the precise thickness needed to ensure both safety and cost-effectiveness.

Economic Advantages of Lightweight Concrete Floors

The initial cost of a lightweight concrete floor system is generally higher than that of traditional concrete systems by less than 1%. However, this additional cost is more than offset by several key benefits:

- Reduced Dead Load: The lower weight of lightweight concrete reduces the load on the foundation and supporting beams, which can result in smaller, less expensive structural elements.

- Smaller Foundation Requirements: Because the building weighs less, foundations can be smaller, leading to significant savings in material costs.

- Reduced Seismic Forces: Lighter buildings experience less inertial force during seismic events, reducing the overall structural demands and improving the safety and resilience of the building.

- Fewer Structural Supports: Precast and prestressed lightweight concrete floors allow for longer spans, reducing the number of columns and beams required, further decreasing costs.

- Enhanced Fire Resistance: Lightweight concrete has better fire resistance compared to normal concrete, allowing for thinner slabs, which reduces the amount of concrete needed and lowers costs.

These economic advantages make lightweight concrete floors a smart investment in terms of both initial construction and long-term maintenance.

Applications of Lightweight Concrete Floors

Lightweight concrete floors are used in a wide variety of building types, including:

- Steel Frame Offices: Reducing weight and enhancing the structural efficiency of steel frame buildings.

- Commercial Buildings: Offering cost-effective, durable, and flexible floor systems for office spaces, retail centers, and shopping malls.

- Industrial Buildings and Warehouses: Providing robust flooring systems that can handle heavy loads while reducing structural requirements.

- Leisure Buildings, Hospitals, Schools, Cinemas: Lightweight floors allow for large, open spaces while reducing construction time and material costs.

- Residential Buildings and Individual Houses: Lightweight concrete floors are also increasingly being used in homes, offering energy efficiency, fire resistance, and ease of construction.

- Refurbishment Projects: Lightweight concrete is perfect for renovation projects where reducing structural load is a priority.

Lightweight concrete floors represent a modern and efficient solution for a wide range of construction needs. By offering superior strength-to-weight ratios, cost savings, and structural efficiency, these floors are quickly becoming the preferred choice in both new construction and refurbishment projects. As the demand for sustainable and cost-effective building materials continues to grow, lightweight concrete will likely play an increasingly important role in the future of construction.