Reinforced concrete (RC) structures and steel structures are fundamental to modern construction, each offering unique advantages and limitations. While both follow a similar load transfer mechanism, the materials, construction techniques, and performance characteristics differ significantly. Understanding these differences is crucial when selecting the appropriate type of structure for a project. This article explores these distinctions across several critical factors.

Material

The primary difference lies in the materials used. RC structures are constructed using reinforced cement concrete (RCC), which combines the compressive strength of concrete with the tensile strength of steel reinforcement to bear loads effectively. In contrast, steel structures rely entirely on steel as the load-bearing material, offering unmatched strength and flexibility.

Cross-Section of Structural Elements

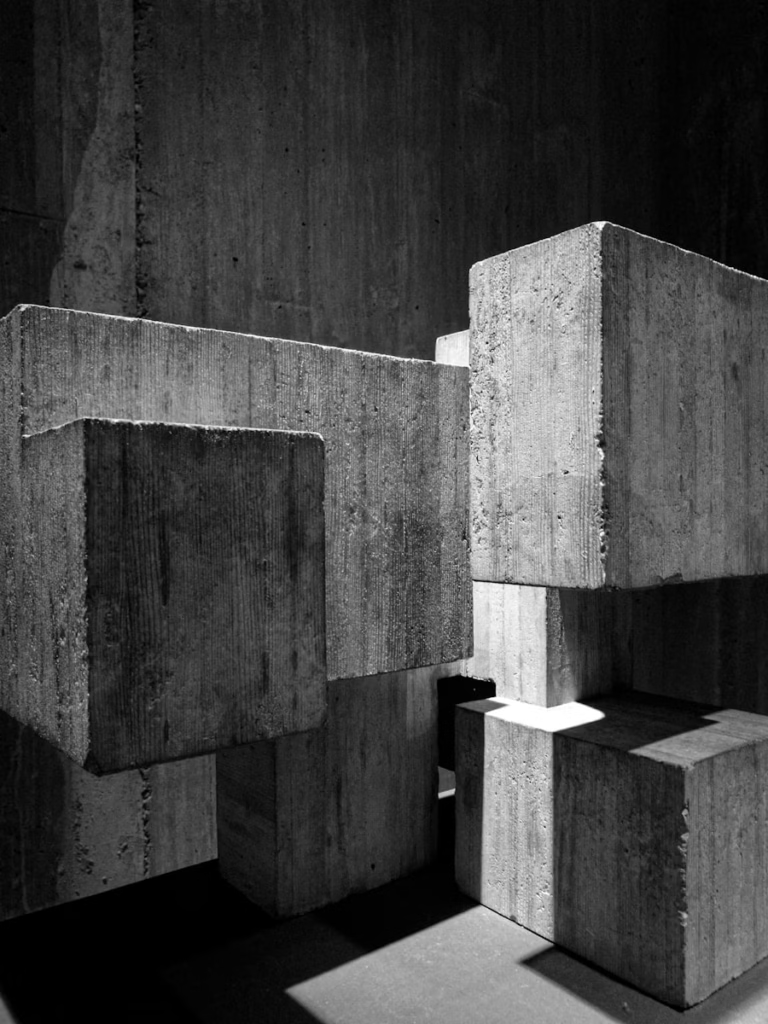

RC structures typically require larger cross-sections for their structural elements. The bulkiness ensures strength and stability but increases the material usage. Conversely, steel structures feature smaller, more efficient cross-sections, optimizing the use of material while maintaining structural integrity.

Durability

Durability is a notable strength of RC structures, which are less affected by common environmental and weather conditions. High-quality RCC constructions can withstand exposure over time without significant degradation. On the other hand, steel structures are prone to rust and corrosion when exposed to moisture or harsh environments unless treated with protective coatings.

Resistance to Earthquake and Dynamic Loads

The response to dynamic loads, such as earthquakes and wind, sets these structures apart. RC structures are brittle in nature, making them less resistant to such forces. In contrast, steel structures exhibit ductility, which allows them to absorb and dissipate energy during dynamic events, making them more resilient.

Load Carrying Capacity

Steel structures excel in load-carrying capacity, outperforming RC structures, which are comparatively weaker. This makes steel the material of choice for projects requiring significant load-bearing capabilities.

Self-Weight

The self-weight of RC structures is high due to the heavy use of raw materials like cement, sand, and aggregates. Steel structures, on the other hand, are much lighter—roughly 60% lighter than their concrete counterparts—making them suitable for applications where weight is a critical factor.

Foundation Requirements

Because of their significant dead weight, RC structures demand robust foundations to support the load. Steel structures, being lighter, impose less pressure on the foundation and can often be built on simpler and less expensive foundations.

Tensile Strength

RC structures have limited tensile strength due to the inherent properties of concrete. While steel reinforcement enhances this capacity, it still falls short compared to steel structures, where tensile strength is significantly higher.

Labor Requirement

The construction of RC structures is labor-intensive, involving multiple stages such as formwork, concreting, and curing. In contrast, steel structures require less labor as most components are fabricated in workshops and assembled on-site, streamlining the process.

Construction Process

The RC construction process is straightforward but time-consuming due to the need for curing and setting. In comparison, steel structures are faster to build, with pre-fabricated components reducing on-site construction time.

Cost of Construction

When it comes to cost, RC structures are generally more economical, making them ideal for budget-conscious projects. However, steel structures tend to be costlier due to material and fabrication expenses.

Construction Speed

The speed of construction is a distinct advantage of steel structures, as prefabrication allows rapid assembly. In contrast, RC structures require extended time for processes like concreting and curing.

Quality Control

Maintaining consistent quality during RC construction is challenging due to variations in material properties and workmanship. Steel structures, on the other hand, allow better quality control since components are manufactured in controlled environments.

Fire Resistance

RC structures offer superior fire resistance, as concrete can withstand high temperatures without losing its structural integrity. Steel structures are less fire-resistant, requiring additional measures such as fireproofing to enhance safety.

Scrap Value

At the end of its lifecycle, steel structures provide good scrap value, making them recyclable and environmentally friendly. RC structures, however, have no significant scrap value, resulting in disposal challenges.

Corrosion

Properly designed and constructed RC structures are resistant to corrosion, even in challenging environments. Steel structures, however, are susceptible to corrosion unless adequately protected, requiring periodic maintenance.

Repair and Maintenance

Repairs and maintenance can be a challenge for RC structures, as they are time-consuming and labor-intensive. In contrast, steel structures are easier to repair, and their maintenance costs are generally lower.

Conclusion

The choice between RC structures and steel structures depends on various factors, including the specific requirements of the project, environmental conditions, budget, and timeline. RC structures are favored for their durability, fire resistance, and cost-effectiveness, making them suitable for residential and infrastructure projects. Steel structures, with their high strength, ductility, and speed of construction, are ideal for industrial buildings and projects requiring rapid assembly. By understanding these differences, stakeholders can make informed decisions to achieve the best outcomes for their construction needs.