Concrete structures are among the most widely used elements in modern construction due to their versatility and strength. However, concrete alone is brittle under tension, which necessitates the addition of steel reinforcement. The balance of steel in reinforced concrete structures is governed by minimum and maximum reinforcement ratios. These ratios ensure safety, durability, and cost-effectiveness while preventing premature failure or inefficiencies.

Understanding Reinforcement Ratios

Minimum Reinforcement Ratio

The minimum reinforcement ratio is the smallest steel area required in concrete members to prevent abrupt failure after the material loses its tensile strength. This ratio ensures that structural elements maintain sufficient ductility and crack control.

Maximum Reinforcement Ratio

On the other hand, the maximum reinforcement ratio is the upper limit of steel reinforcement. Beyond this threshold, concrete may fail in compression before the full capacity of the steel reinforcement is utilized. It also avoids issues like steel congestion, which can hinder proper concrete placement and compaction.

Minimum Reinforcement Ratio: Purpose and Applications

Purpose

The primary purpose of minimum reinforcement is to:

- Control cracking in concrete structures, particularly in tension zones.

- Ensure the member retains sufficient ductility to prevent sudden, catastrophic failures.

- Provide a baseline for the safe design of structural members in accordance with building codes like ACI 318-19.

Applications in Structural Elements

The minimum reinforcement ratio varies depending on the type of structural member:

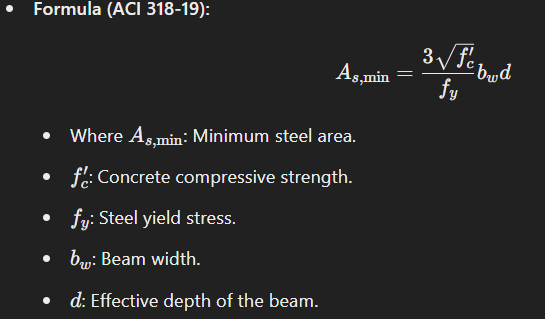

1. Beams

In reinforced concrete beams, cracking occurs when the tensile stress in concrete exceeds its tensile strength. If the cracked section lacks adequate reinforcement, it may fail suddenly upon the formation of the first crack. To prevent this, a minimum area of steel reinforcement is required.

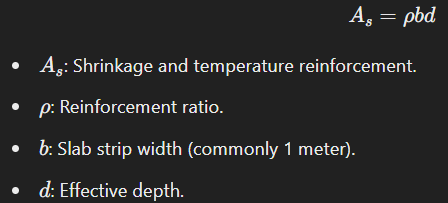

2. Slabs

In slabs, reinforcement primarily addresses cracks due to temperature changes and shrinkage. This reinforcement ensures structural integrity without exceeding the design requirements for shrinkage and thermal stresses.

- Formula:

3. Uniform Footing

Footings, like slabs, rely on temperature and shrinkage reinforcement to control cracks. The minimum reinforcement ratio here is similar to that of slabs and ensures uniform stress distribution under the column load.

4. Columns

Columns require reinforcement to resist unexpected bending moments, which may arise due to misalignment or eccentric loads. The minimum ratio also reduces shrinkage and creep effects in concrete under sustained compressive stress.

- ACI 318-19 Specification:

ρmin=0.01×gross column area

5. Connections

At connections, such as between cast-in-place columns and foundations, minimum reinforcement ensures the structural integrity of interfaces. ACI 318-19 specifies that the reinforcement crossing the column-foundation interface should be at least:

As=0.005×gross supported member area.

Maximum Reinforcement Ratio: Ensuring Economy and Safety

Purpose

The maximum reinforcement ratio is critical for preventing concrete crushing, an undesired mode of failure. It ensures:

- Efficient utilization of steel reinforcement.

- Prevention of over-reinforcement, which can lead to excessive costs without proportional benefits.

- Adequate compaction of concrete around reinforcement to maintain structural integrity.

Applications in Structural Elements

The maximum reinforcement ratio varies based on the structural component and the constraints they face.

1. Beams

Over-reinforcing a beam can cause it to fail in compression before the tensile steel achieves its full strength. This undesirable failure mode is prevented by adhering to the maximum reinforcement ratio set by codes.

2. Columns

For columns, excessive steel area can result in steel congestion, complicating concrete placement and reducing compaction quality. The ACI 318-19 specifies:

ρmax=0.08×gross area of column.

Practically, designers often limit reinforcement to ( ρmax = 0.04 ) for splicing locations to ensure sufficient concrete cover and avoid congestion.

Shear Reinforcement: Supplementing Flexural Design

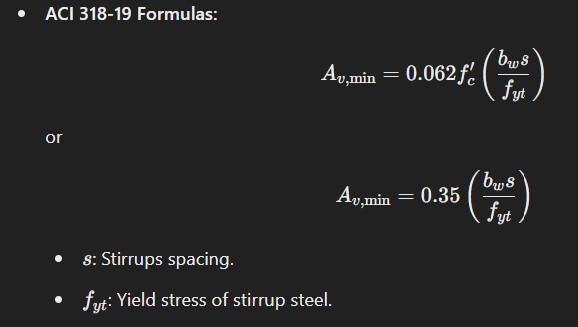

Minimum Shear Reinforcement in Beams

Shear reinforcement is essential in regions where the applied shear exceeds half the concrete’s shear strength. This reinforcement prevents brittle shear failure, which can occur suddenly without warning.

- ACI 318-19 Formulas:

Walls: Longitudinal and Transverse Reinforcement

In cast-in-place walls, reinforcement ratios depend on the in-plane shear demand. If applied shear is low, minimum reinforcement values provided in ACI 318-19 Table 1 can be used. For higher shear, longitudinal and transverse reinforcement ratios are adjusted accordingly.

Conclusion: Balancing Safety and Efficiency

The balance of reinforcement in concrete structures is crucial for achieving both safety and cost-efficiency. While minimum reinforcement ratios ensure crack control and ductility, maximum reinforcement ratios prevent brittle failures and maintain economic feasibility. Proper application of these principles ensures the durability and reliability of concrete structures, adhering to standards such as ACI 318-19. By understanding and applying these guidelines, engineers can design concrete members that meet the demands of modern construction while ensuring long-term performance.