In building design, energy efficiency has become a crucial focus for reducing operational costs and environmental impact. A fundamental metric that determines a building’s insulation performance is the U-value, which measures the rate of heat transfer through materials. A lower U-value represents better insulation, signifying a material’s effectiveness in reducing energy loss. This article dives into the concept of U-values, their calculation, application across different building materials, and the science behind thermal resistance.

Introduction to U-Value

The U-value of a building component, such as a wall or window, quantifies the amount of heat energy (measured in Watts) that passes through a square meter of material for each degree Celsius difference in temperature between the interior and exterior environments. The measurement unit for U-value is (W/m^2K) (Watts-per-meter-square-kelvin), with “K” representing the temperature difference. High U-values indicate rapid heat transfer, while low U-values indicate slower heat transfer, signifying more effective insulation. U-value plays an essential role in assessing how well a building can retain warmth during winter or keep cool air from escaping in summer, directly affecting energy efficiency.

Purpose of U-Value in Building Design

U-values provide a measurable benchmark for understanding the insulating performance of building components, helping designers and engineers select materials that align with energy conservation goals. Components with low U-values help buildings maintain internal temperature more effectively, reducing the need for extensive heating or cooling systems. The U-value assessment applies to both homogeneous materials (e.g., concrete) and composite materials (e.g., cavity walls that combine brick and insulation). As insulation performance improves, the U-value decreases, reflecting the component’s efficiency in limiting heat transfer and supporting indoor climate control.

Key Features of U-Value

- Insulation Performance and Heat Transmittance: The U-value is inversely related to insulation performance. A lower U-value means slower heat transmittance, indicating that the material or structure can keep heat from flowing in or out, acting as a better insulator.

- Strategies for Reducing U-Values: To achieve lower U-values, building designs integrate materials and construction techniques that reduce heat loss. This approach includes adding insulation layers, selecting materials with low thermal conductivity, and using energy-efficient glazing for windows.

- Regulatory Standards for U-Values: Many building regulations stipulate maximum permissible U-values for walls, roofs, floors, and windows, promoting energy efficiency. Adhering to these standards minimizes energy consumption and operational costs.

- Variation Across Building Components: Different materials exhibit unique U-values based on their thermal properties. For example, a solid brick wall has a higher U-value than an insulated cavity wall, reflecting greater heat loss. Modern materials like triple-glazed windows feature substantially lower U-values, enhancing insulation.

U-Values for Different Building Materials

Below are U-values for common building materials and how they compare in terms of energy efficiency:

- Solid Brick Wall: Typically, a solid brick wall has a U-value around 2 W/(m²K), which is relatively high and indicates substantial heat transfer.

- Cavity Wall (No Insulation): A cavity wall without insulation has a U-value around 1.5 W/(m²K), offering moderate insulation but benefiting from additional layers.

- Insulated Wall: Adding insulation significantly improves performance, with U-values as low as 0.18 W/(m²K), making insulated walls a popular choice for energy-efficient buildings.

- Window Glazing Options:

- Single Glazing: Single-pane glass has U-values between 4.8 and 5.8 W/(m²K), resulting in considerable heat loss.

- Double Glazing: Double glazing can reduce the U-value to between 1.2 and 3.7 W/(m²K), depending on gas fillings and spacer types.

- Triple Glazing: With values below 1 W/(m²K), triple glazing provides excellent insulation, suitable for high-performance, energy-efficient buildings.

- Solid Timber Door: Generally, solid timber doors have a U-value around 3 W/(m²K), indicating modest insulation relative to modern alternatives.

Designing buildings with materials that have low U-values is a critical component of sustainable architecture, reducing the demand for energy-intensive heating and cooling systems.

Calculation of U-Value (Thermal Transmittance)

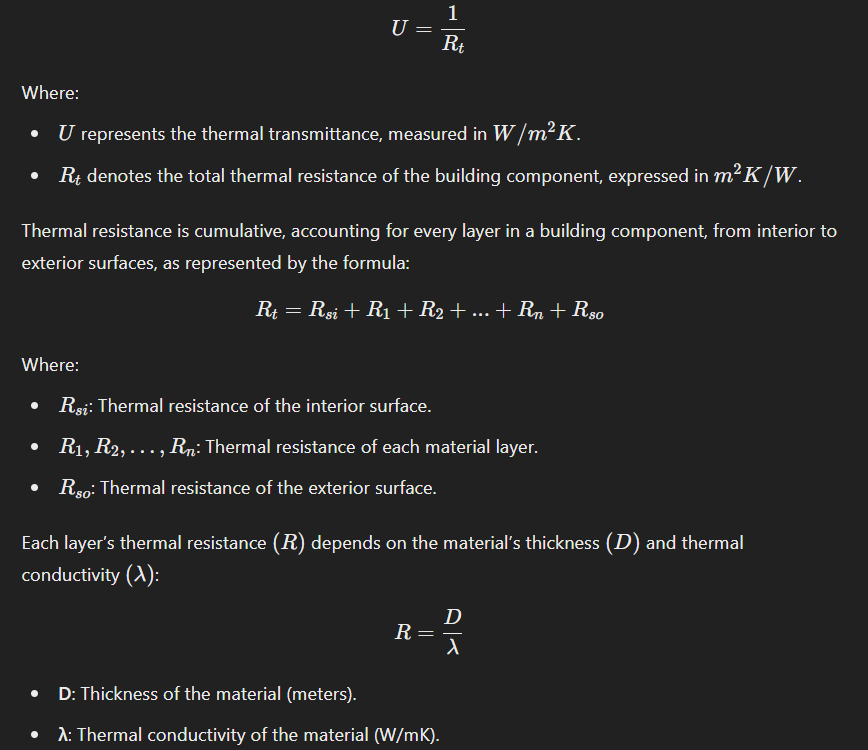

The U-value can be calculated using the formula:

A material’s thickness and thermal conductivity largely determine its resistance to heat transfer. For instance, a thick, low-conductivity layer offers substantial resistance, lowering the overall U-value.

Relationship Between U-Value and Thermal Resistance

U-value is inversely related to the total thermal resistance ( (R_t) ). As ( R_t ) increases due to high-resistance materials or added insulation, the U-value decreases, indicating improved insulation. For example, adding layers with high thermal resistance to a wall system reduces heat transfer, lowering the U-value and energy loss.

Example Calculation:

A single-glazed window with a U-value of 6 W/(m²K) indicates that each degree of temperature difference between indoors and outdoors results in a heat loss of 6 watts per square meter. On a cold day with a 15-degree temperature differential, this window loses 90 watts per square meter—an inefficient outcome compared to modern triple-glazing options, which can bring the U-value down to 0.7 W/(m²K).

Conclusion

U-value is a crucial metric in building design, shaping the way materials are chosen to balance indoor climate control and energy efficiency. By targeting low U-values, builders and architects can ensure better insulation, reducing heating and cooling requirements and promoting sustainable practices. Understanding U-values and integrating materials with optimized thermal resistance play a pivotal role in designing energy-efficient buildings that meet modern regulatory standards, ultimately contributing to lower operational costs and environmental conservation.

This comprehensive article underscores the importance of U-values and their practical application in building design, offering a framework for selecting materials that support energy efficiency and sustainable construction.