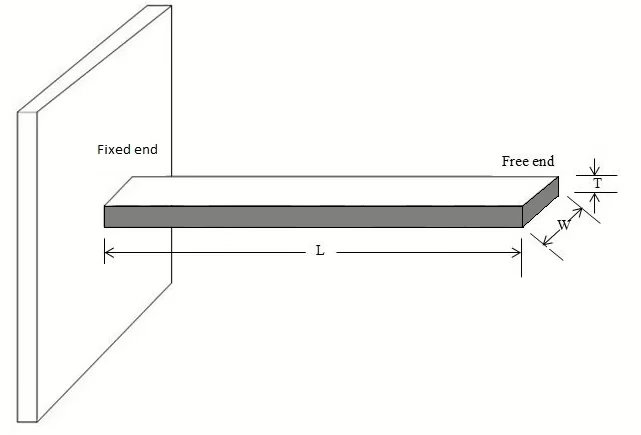

A cantilever beam is a rigid structural element supported at one end and free at the other. This unique design allows the beam to extend beyond its support, making it a versatile and useful component in various construction projects. Cantilever beams are commonly made of concrete or steel, with one end anchored or cast into a vertical support while the other end remains free to carry loads. These beams are typically horizontal in orientation, and their free end is often subjected to vertical loads

In building construction, cantilever beams are often used as extensions of continuous beams. In bridges, they serve as part of the cantilever girder system. Their construction can be done through cast-in-situ methods or segmental construction, sometimes utilizing pre-stressing techniques. One of the key advantages of cantilever beam design is that it allows structures to overhang without the need for additional supports or bracing, offering both functionality and aesthetic appeal. This article will explore the structural actions, design considerations, and applications of cantilever beams in construction.

Structural Behavior of Cantilever Beams

When a cantilever beam is subjected to vertical loads, it bends downward. This bending, regardless of the load type (point load, uniform load, or varying load), creates a convexity upward. The bending action induces tension in the upper fiber and compression in the lower fibers of the beam. This differential stress is a key factor in designing cantilever beams, as the upper fibers must be reinforced to handle the tensile forces.

For example, consider a cantilever beam subjected to a point load at its free end. The load causes the beam to bend downward, as illustrated in Figure-2. The upper part of the beam experiences tension, while the lower part experiences compression. Proper reinforcement, typically in the form of steel bars placed in the upper portion of a concrete beam, helps ensure that the tensile stresses are safely managed.

Shear Force and Bending Moment

The shear force at any point along the length of a cantilever beam is the sum of all loads applied between that point and the free end. Similarly, the bending moment at any given section is calculated as the sum of all moments created by the loads between that section and the free end.

For instance, consider a cantilever beam with a point load at the free end. At any section along the beam, the shear force is constant, while the bending moment varies depending on the distance from the fixed support. The shear force at the fixed support will equal the total load, while the bending moment at the support will be equal to the total load multiplied by the length of the beam.

Shear force and bending moment diagrams are essential tools in designing cantilever beams, as they help engineers understand how the beam will respond to various load scenarios. These diagrams are created by considering different combinations of dead and live loads, following design standards to ensure safety and stability.

Design of Cantilever Beams

Cantilever beams are subject to both moment and shear stresses, which must be transferred safely to the support. The main objective of any design process is to ensure that these stresses are properly managed. The bending moment in a cantilever beam varies along its length, with the maximum moment occurring at the fixed support and decreasing to zero at the free end.

During the design phase, it is crucial to reinforce the upper fiber of the beam, as this is where the highest tensile stress occurs. The amount of reinforcement required depends on several factors, including the magnitude and type of load, the length of the beam, and the properties of the material used.

The maximum span of a cantilever beam is influenced by several factors:

- Beam Depth: Increasing the depth of the beam can help support a longer span.

- Load Characteristics: The type, magnitude, and location of the applied load play a significant role in determining the beam’s span.

- Material Quality: Stronger materials, such as steel or pre-stressed concrete, can allow for longer spans.

For smaller cantilever beams, the span is typically limited to 2 to 3 meters. However, by increasing the beam’s depth or utilizing more advanced materials, such as pre-stressed concrete or steel, longer spans can be achieved. Proper analysis and design are essential to ensure that the cantilever beam can safely transfer the generated moments to the ground.

Applications of Cantilever Beams in Construction

Cantilever beams are used in a variety of construction applications due to their ability to extend without the need for additional support structures. Some common applications include:

- Cantilever Balconies: Cantilever beams allow balconies to project outward from the main structure without the need for external supports.

- Temporary Cantilever Support Structures: Used in construction staging, these beams support temporary structures and scaffolding.

- Freestanding Radio Towers: Cantilever beams are employed to build tall, freestanding towers, eliminating the need for guy wires.

- Pergolas: Cantilever beams are used to support open-air structures such as pergolas, providing a clean and simple design.

- Lintels: In building construction, cantilever beams are often used as lintels to support the weight of walls above doorways and windows.

These applications highlight the versatility and importance of cantilever beams in modern construction.

Advantages and Disadvantages of Cantilever Beams

Like any structural element, cantilever beams come with both advantages and disadvantages.

Advantages:

- No Need for Opposite Support: Cantilever beams can extend beyond their support without requiring additional structural elements on the opposite side.

- Negative Bending Moment: The negative bending moment created by cantilever beams helps counteract positive bending moments in other parts of the structure, enhancing overall stability.

- Ease of Construction: Cantilever beams can be relatively simple to construct, especially when using pre-stressed or steel materials.

Disadvantages:

- Large Deflections: Cantilever beams are prone to larger deflections, which may need to be controlled through design adjustments.

- Larger Moments: The bending moments in cantilever beams can be significantly larger compared to simply supported beams, which requires careful design and reinforcement.

- Need for Strong Fixed Support: To ensure stability, a strong fixed support or backspan is essential, as cantilever beams rely heavily on this point for structural integrity.

Conclusion

Cantilever beams are essential structural elements in modern construction, offering a unique solution for overhanging structures without the need for additional supports. They provide aesthetic value, functionality, and strength in buildings, bridges, and various other applications. However, their design and construction require careful attention to factors such as load types, reinforcement, and support conditions to ensure safety and stability. Understanding the structural behavior, shear force and bending moment distribution, and the advantages and limitations of cantilever beams is crucial for engineers and architects when incorporating them into any project.