Composite steel joists have long been recognized as one of the most economical systems for constructing building floors. Over the years, engineers and builders have developed three primary options to meet height limitations and accommodate complex mechanical, electrical, and communication systems:

Among these, composite joists stand out as efficient load-carrying members that provide superior structural performance.

Definition of Composite Steel Joists

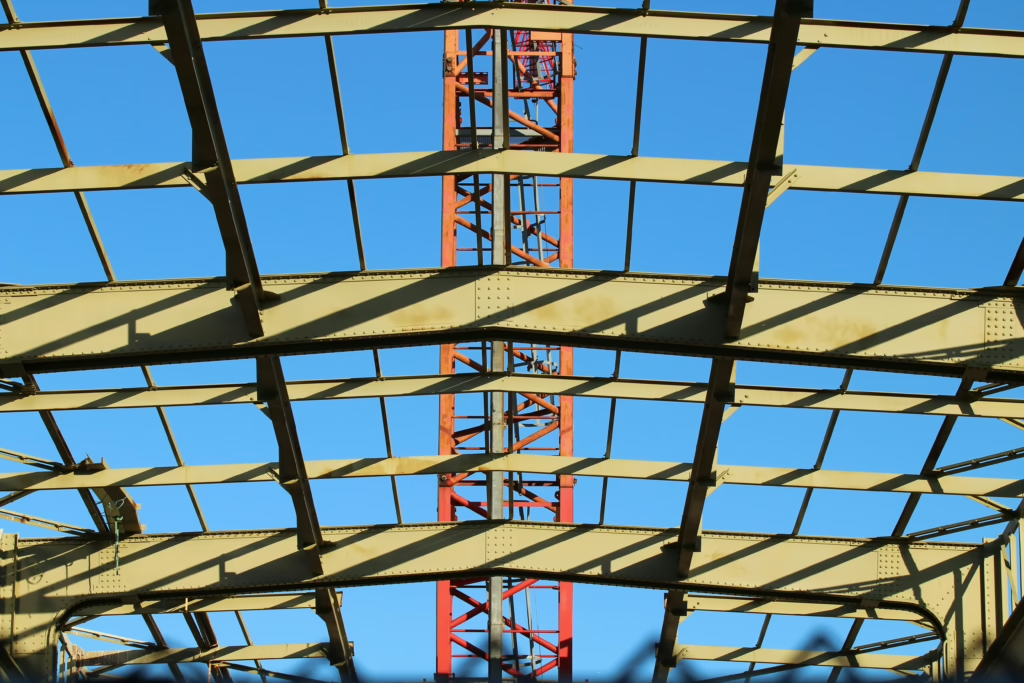

A composite steel joist is an open web, parallel chord member designed to support floors in buildings. It is made from hot-rolled or cold-formed steel, including steel that has undergone cold working to achieve its yield strength. The integration of a concrete slab and steel joist is achieved through shear connection, enabling both materials to function as a single, unified structural system once the concrete has properly cured.

Shear Connection Methods

The shear connection between the joist top chord and the concrete slab is crucial for composite action. Several methods are commonly used, including:

- Specially rolled cold-formed steel “S” shaped top chords (Hambro)

- Specially embossed back-to-back double-angle top chords (Vescom)

- Perforated structural tee top chords (Taftrus)

- Shear studs welded through the metal deck (Canam, SMI, Vulcraft)

These methods ensure a strong and effective bond between the steel joist and the concrete slab, allowing for optimal load distribution and enhanced structural integrity.

Advantages of Composite Steel Joists

Using composite steel joists offers numerous benefits, including:

- Efficient Routing of Mechanical Systems – The open web design allows mechanical, plumbing, and electrical lines to pass through the joists, reducing obstructions and improving space utilization.

- Flexibility for Future Modifications – HVAC systems can be relocated or adjusted without significant structural modifications.

- Better Plenum Space Utilization – The efficient design optimizes the use of plenum space, allowing for improved airflow and system organization.

- Reduced Floor-to-Floor Height – By integrating mechanical systems within the joist space, overall building height can be minimized without compromising functionality.

- Weight Savings and Cost Reduction – The optimized joist design reduces the overall weight of the building, leading to material savings and lower construction costs.

- Simplified Construction and Fast Installation – The design allows for quicker erection and simpler connections, speeding up the construction process.

- Large Column-Free Areas – The ability to span larger distances provides more flexibility in floor layouts, making spaces more adaptable for various uses.

- Customizable Designs – Composite steel joists can be engineered to meet specific load-bearing and serviceability requirements, enhancing their versatility for different projects.

Conclusion

Composite steel joists continue to play a vital role in modern construction, offering cost-effective solutions for floor systems that require strength, efficiency, and flexibility. Their ability to integrate mechanical systems within the structural framework, along with their reduced weight and simplified construction process, makes them an attractive choice for engineers and architects alike. As building designs evolve, composite steel joists remain a key component in creating efficient and adaptable structures.