Reinforcement corrosion and structural deterioration represent significant challenges in civil engineering, affecting the durability, safety, and longevity of concrete structures. Understanding how to prevent these issues is crucial for sustainable infrastructure development and management.

The Comprehensive Prevention Timeline

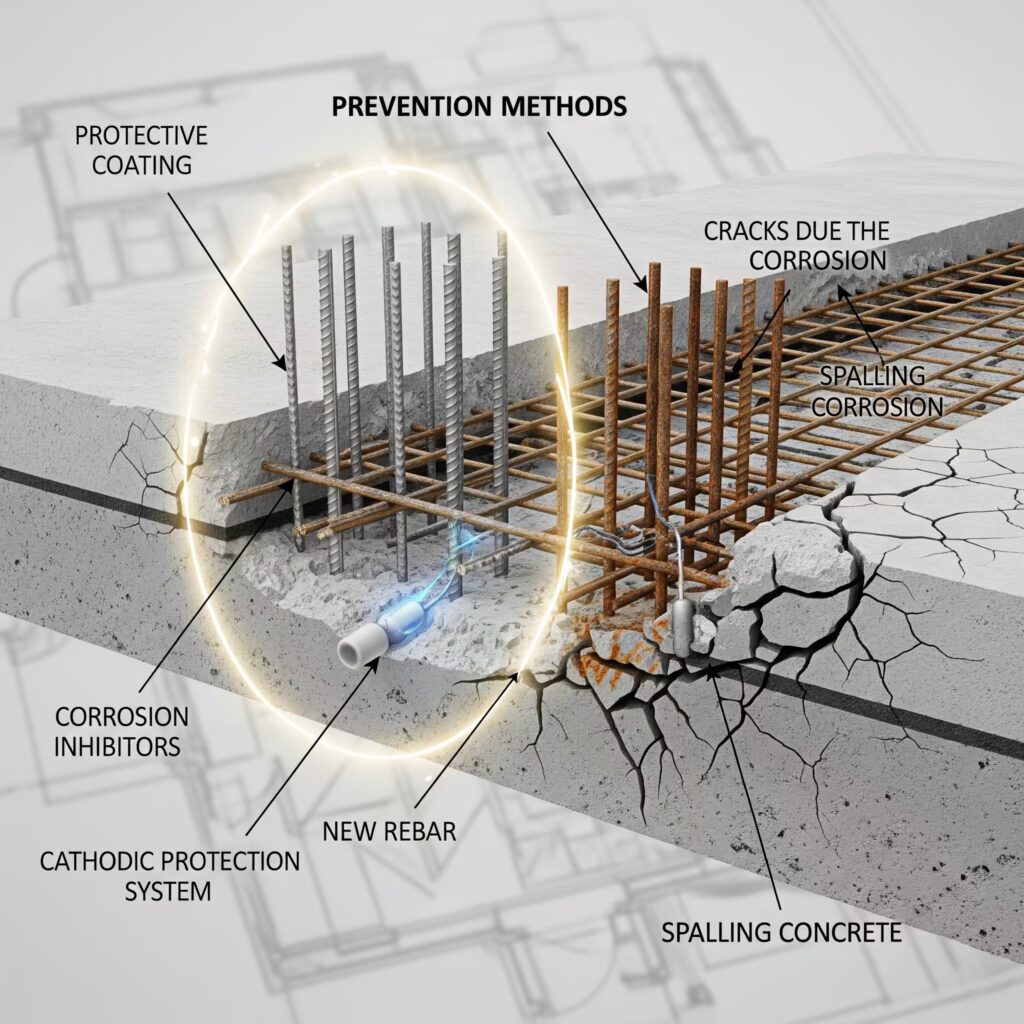

Prevention of reinforcement corrosion and other types of deterioration begins in the design phase, when a structure is conceived and structural calculations are made. During this crucial initial stage, engineers must carefully design details, select appropriate materials and their proportions, and consider possible additional preventative measures. The choices made at this juncture profoundly influence the structure’s resistance to deterioration throughout its service life.

Prevention efforts continue as the project moves into the construction phase. The quality of concrete preparation, placement, compaction, and curing all play vital roles in creating a durable structure resistant to corrosion. Poor execution during these steps can compromise even the best design intentions, creating vulnerabilities that may manifest years later.

However, prevention doesn’t end once construction is complete. It will continue throughout the entire service life of the structure, with programmed inspections, monitoring, and maintenance forming a critical ongoing defense against deterioration. This lifecycle approach recognizes that concrete structures are not static entities but dynamic systems requiring ongoing attention.

Increasing Professional Awareness

Civil engineers have become increasingly aware of the importance of these matters in recent decades. This heightened awareness reflects a growing understanding that proactive prevention is more cost-effective than reactive repairs. Various international organizations have recognized this shift and provided valuable guidance on best practices for corrosion prevention, helping to standardize approaches across the industry.

The Economics of Prevention

The concept of prevention as a sequence of events with increasing levels of costs carries important implications for structural design and management. Early intervention is inherently more economical than addressing problems after they’ve developed. This economic reality underscores why structures should be accessible to inspection and maintenance.

When accessibility is limited, such as in underground structures, even more emphasis must be placed on service life design. These structures require particularly robust initial designs since regular inspection and maintenance may be challenging or impossible. The initial investment in superior materials and design becomes justified given the difficulty of future interventions.

Integrating Maintenance into Design

On the other hand, if planned and regular inspection, monitoring, and maintenance of the structure are taken into account in the design stage, certain requirements could potentially be relaxed. At least theoretically, programmed maintenance could be included in the design, allowing for more optimized use of materials and resources with the understanding that regular maintenance will compensate for these optimizations.

Practical Applications in Modern Engineering

For relatively short-lived components or materials, this integration of maintenance into design is already done in practice. For example, some bridges utilize precast sidewalks designed to be replaced after a predetermined period. Similarly, vehicle barriers in tunnels are often designed with the expectation of eventual replacement. These components serve as sacrificial elements, protecting more critical structural components and simplifying maintenance operations.

Another practical example is the prescheduled re-application of protective coatings. Rather than waiting for visible deterioration, maintenance plans may call for new coatings at regular intervals, ensuring continuous protection and preventing the opportunity for corrosion to begin.

Conclusion

Prevention of reinforcement corrosion requires a comprehensive approach spanning from initial design through the entire service life of a structure. By considering maintenance requirements during design, planning for accessibility, and scheduling interventions before problems develop, engineers can create more durable, economical structures that maintain their integrity for generations. As awareness of these principles continues to grow, we can expect to see increasingly sophisticated approaches to corrosion prevention that further extend the service life of our built environment.