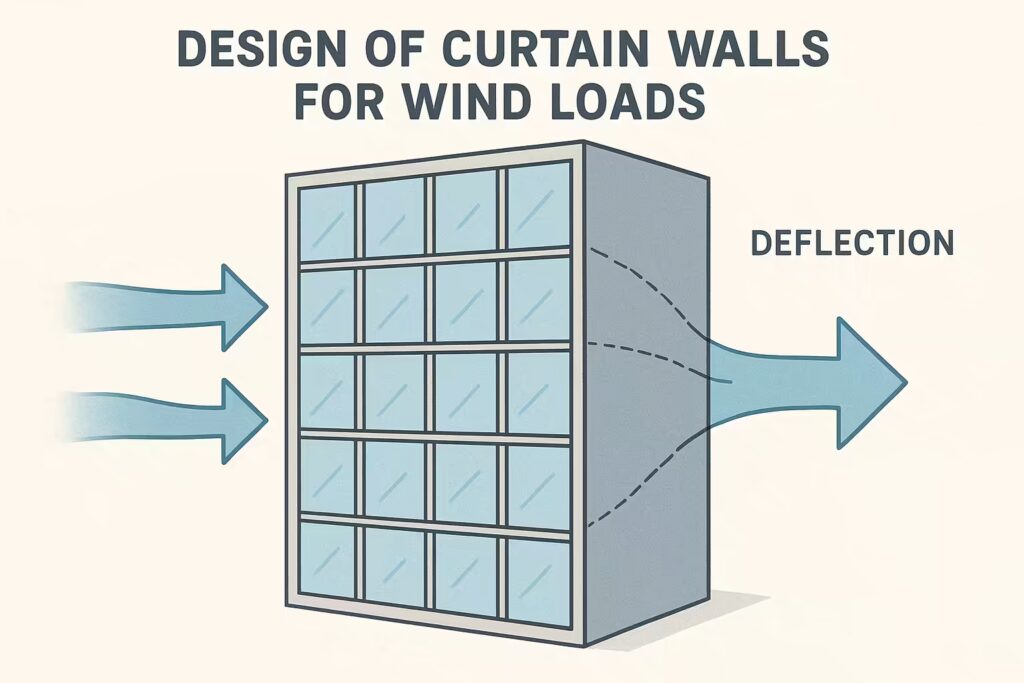

Curtain walls are a critical component of modern buildings, providing both aesthetic appeal and structural integrity. They are the first structural elements subjected to wind loads, making their design crucial for ensuring safety and stability. The structural design of curtain walls for wind loads requires careful analysis of aerodynamic factors, material composition, and attachment mechanisms.

Structural Elements Influencing Curtain Wall Design

One of the most significant factors in curtain wall design is the role of floor slabs, which provide anchor points for the system. Curtain walls are typically arranged as vertical members attached to the floor slabs, spanning continuously from floor to floor.

Wind Loads and Curtain Wall Design Considerations

Key Factors in Design:

- Structural load path – how wind forces are transferred through the system.

- Glass thickness selection – ensuring structural integrity and safety.

- Attachment mechanisms – securing glass panes to the frame.

- Scale importance – precision in sizing and fitting.

- Manufacturing and placement – practical considerations in production and installation.

Order of Curtain Wall Structural Design and Load Path

Wind loads impact the glazing panels first, transferring forces to perimeter supports and then to framing members. The horizontal elements between vertical mullions act as secondary members, redistributing part of the dead and wind loads. Openings such as ventilation shafts and doors can alter this load path, making internal pressure considerations essential.

Design of Curtain Wall Glass Thickness

Glass thickness is influenced by:

- Imposed loads such as wind and impact forces.

- Span values and shading temperature effects.

- Strength properties of different glass types (annealed, heat-strengthened, fully tempered).

ASTM E1300 provides guidelines for sizing glass based on geometric and load parameters. Standard commercial curtain walls in the U.S. commonly use 0.635 cm thick glass, with insulated glass units comprising 0.635 cm outer and inner layers separated by a 1.27 cm air gap.

Glass Pane to Frame Attachment Mechanisms

Structural Silicone Glazing:

- Uses adhesive rubber to secure the glass against wind forces.

- No mechanical restraint; relies on engineering expertise.

- Designed to resist in-plane wind forces.

Point Supported Glass:

- Uses clamps, T-headed bolts, and countersunk holes to secure glass.

- Structural support options include spider fittings and cable networks.

- Countersunk holes influence glass thickness selection.

Structural Glass in Curtain Wall Systems

Structural glass, such as fin glass, functions similarly to vertical mullions. While aesthetically appealing, it requires high safety factors due to its potential for sudden failure. Ensuring redundancy through sacrificial plies and alternative load paths is essential.

Importance of Scale in Curtain Wall Design

Unlike concrete or steel structures, curtain walls require extreme precision. Components must be dimensioned within millimeters to ensure proper assembly. Deflection of perimeter spandrel beams due to live loads also impacts curtain wall expansion joints.

Manufacturing and Placement Considerations

Successful curtain wall design balances structural efficiency, material economy, and ease of installation. Coordination between designers, manufacturers, and installers ensures constructability while maintaining performance requirements.

Calculation Procedure for Design Wind Load

ASCE 7-10 provides methods for calculating wind loads:

- Main Wind Force Resisting Systems (MWFRS).

- Components and Cladding (C&C).

Two methods for C&C wind load calculations:

- Analytical Procedure.

- Wind Tunnel Testing.

Analytical procedures (ASCE 7-10, Chapter 30) are commonly used for curtain walls.

Wind Load Combinations

Typical wind load combination:

Wu = 1 Dead Load + 1 Wind Load (ASCE 7-10)

Safety Glazing Considerations

Certain conditions necessitate safety glazing:

- Fire-rated assemblies.

- Overhead glazing.

- Glass in doors and windows.

- Glass near pedestrian pathways.

Building codes outline safety requirements for these applications.

Curtain Wall Analytical Models and Detailing

Key Analysis Techniques:

- Dynamic Pressure to Static Pressure Conversion: Uses Bernoulli’s equation to determine equivalent static pressures.

- Free Body Diagrams: Illustrate load distribution on vertical and horizontal mullions.

- Finite Element Analysis (FEA): 3D modeling with software like ANSYS to simulate curtain wall behavior.

Connection Assemblies and Anchor Designs

Connection Assemblies:

- Most complex part of curtain wall design.

- Requires accurate modeling of boundary conditions.

- Mechanical connections (welds, bolts) modeled as rigid bodies.

Anchor Designs and Embeds:

- Common anchor types: welded steel, bolts, slotted channels.

- Slotted channels are prevalent in high-performance curtain walls.

- Coordination between engineers ensures proper load transfer and flexibility for structural movement.

Conclusion

Curtain wall design for wind loads requires a balance between structural performance, material efficiency, and constructability. Proper analysis, collaboration among professionals, and adherence to industry standards ensure that curtain walls not only meet aesthetic and functional requirements but also provide long-term safety and stability.