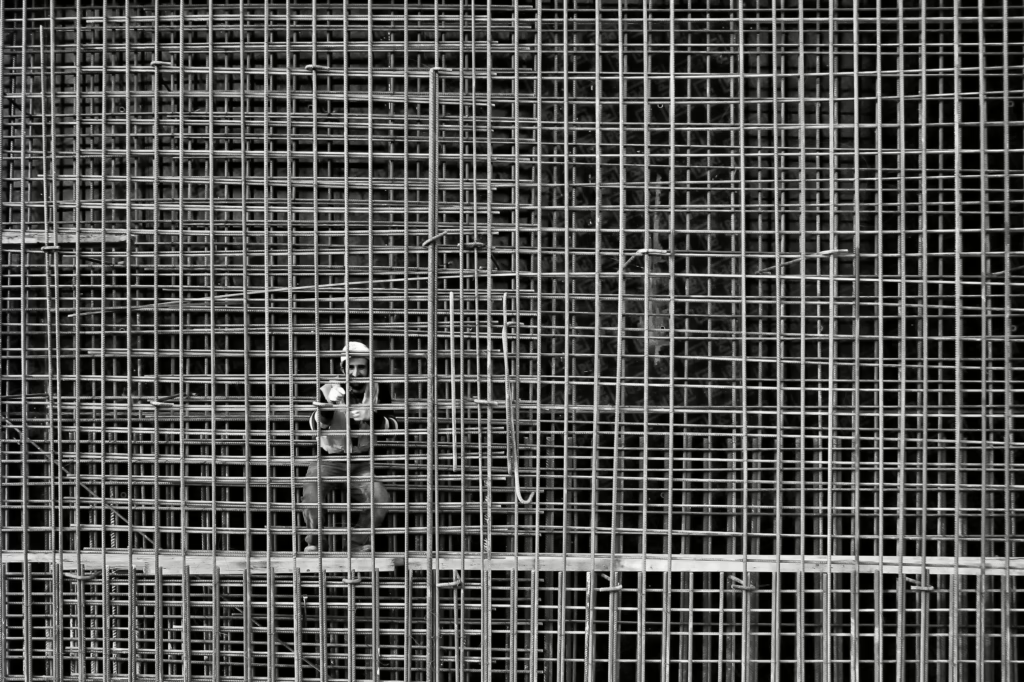

Reinforced concrete design relies on fundamental assumptions that allow engineers to predict the behavior of structural elements under various loads. These assumptions, derived from structural mechanics and extensive experimental testing, serve as the foundation for the design and analysis of reinforced concrete structures. Understanding these principles is crucial for ensuring safety, durability, and functionality in construction.

Purpose of Structural Design

Design is a critical responsibility of structural engineers, involving the determination of the shape, dimensions, and material specifications of a structure. The primary objective of structural design is to ensure that a structure performs its intended function while safely withstanding all applied loads throughout its lifespan. Adhering to fundamental design principles helps achieve stability and longevity in reinforced concrete structures.

Fundamental Assumptions for Reinforced Concrete Behavior

The design and analysis of reinforced concrete are based on the following key assumptions:

1. Equilibrium of Internal and External Forces

At any given section of a reinforced concrete member, the internal forces—such as bending moments, shear forces, and normal and shear stresses—must balance the effects of external loads. This assumption ensures that the structure remains stable and that all forces are properly accounted for in design calculations.

2. Plane Sections Remain Plane After Bending

One of the fundamental principles of reinforced concrete mechanics is that sections perpendicular to the axis of bending before deformation remain plane after bending. This means that any strain distribution across a section remains linear, simplifying stress calculations and making structural analysis more predictable.

3. Perfect Bonding Between Concrete and Steel

It is assumed that there is perfect bonding between concrete and reinforcing steel, meaning there is no slip at the interface. As a result, both materials deform together under loading conditions. Modern deformed bars enhance this bond due to mechanical interlocking and surface adhesion, making this assumption highly accurate in practical applications.

4. Concrete Cannot Resist Tension Stress

Concrete has relatively low tensile strength compared to its compressive strength. When subjected to tensile forces, concrete in the tension zone of a member typically cracks. These cracks, though often microscopic (hairline cracks), indicate that concrete cannot effectively resist tension. Consequently, structural design assumes that all tensile resistance is provided by the reinforcing steel.

Basis of the Theory

The theoretical framework of reinforced concrete design is built upon the actual stress-strain relationships and strength properties of its two primary materials: concrete and steel. By considering these properties, engineers can develop accurate models to predict structural behavior and ensure reliable performance under various loading conditions.

Conclusion

The fundamental assumptions in reinforced concrete design provide a systematic approach for analyzing and constructing safe and efficient structures. These principles ensure equilibrium, account for material behavior, and simplify calculations, making them indispensable tools for structural engineers. Adhering to these assumptions allows for the development of durable and reliable reinforced concrete structures that meet engineering and safety standards.