High-performance steels have become increasingly popular in highway bridge applications due to their high strength, excellent toughness, and resistance to corrosion and fatigue. However, conventional flat web plate girders suffer from potential issues such as web instability, excessive deflections, and fatigue failure. To overcome these challenges, innovative designs such as corrugated webs have been introduced. These corrugated webs enhance shear stability and eliminate the need for transverse stiffeners.

Corrugated steel plates have been used in various structural applications since the 1920s, initially in aircraft structures and later in civil engineering for buildings and bridges. One of the earliest applications in bridge construction was the Cognac Bridge in France, completed in 1986. This three-span continuous box girder bridge showcased the benefits of corrugated steel webs by replacing conventional prestressed concrete bridge webs with corrugated steel ones.

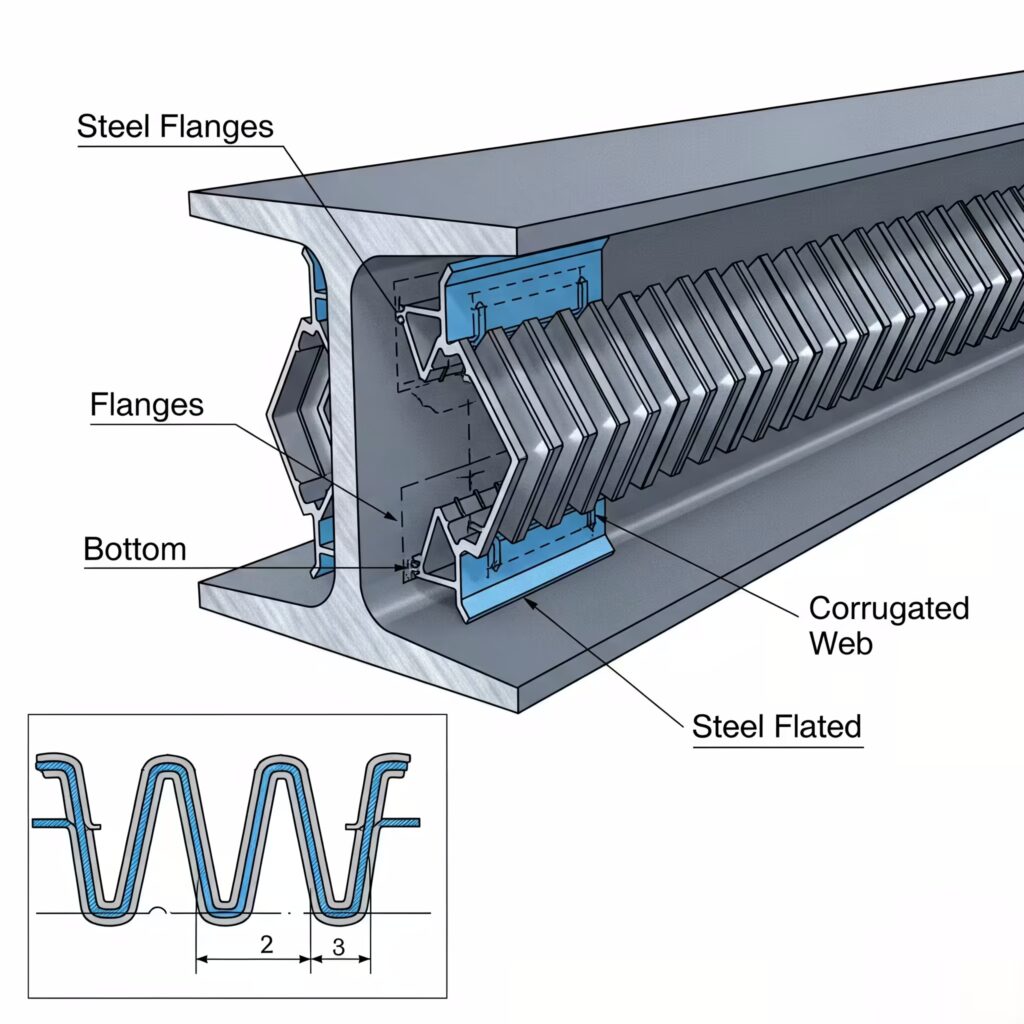

The Corrugated Web Girder Structural System

The corrugated web girder structural system consists of thin-walled corrugated webs and flanges. In plate girder bridges with flat webs, achieving maximum moment-carrying capacity requires slender sections, which are susceptible to web buckling. By incorporating corrugated webs, the need for transverse stiffeners is eliminated, thereby reducing fabrication costs and improving fatigue resistance. These girders are estimated to be 9-13% lighter than conventional stiffened girders with flat webs.

Types of Corrugations

Several types of corrugation profiles exist, including rectangular, trapezoidal, and sinusoidal. Among these, trapezoidal and sinusoidal corrugations are the most widely used due to their superior mechanical properties and structural efficiency.

Purpose of Corrugations

To optimize the cross-section for resisting in-plane bending, maximum material must be positioned as far away from the neutral axis as possible. Increasing section depth results in a more slender web, which could lead to premature failure due to shear buckling. Corrugations reduce the slenderness ratio and provide stability against elastic buckling, eliminating the need for additional stiffeners.

Structural Behavior of Corrugated Webs

Flexural Behavior

The flexural strength of girders with corrugated web plates is primarily provided by the flanges, with minimal contribution from the web. There is no significant interaction between flexure and shear behavior. The corrugated steel web serves mainly to resist shear forces, with its strength controlled by shear buckling and steel yielding. This phenomenon, known as the “accordion effect,” is particularly useful in prestressed concrete bridge girders, where it allows for efficient prestressing of upper and lower decks, reducing prestress losses compared to conventional box girder bridges.

Shear Behavior

Experimental studies confirm that corrugated steel webs are solely responsible for resisting shear forces. Shear strength is influenced by factors such as web height, thickness, corrugation geometry, and web imperfections. Unlike conventional flat web plate girders, corrugated webs provide enhanced shear resistance without requiring transverse stiffeners.

Modes of Failure of Corrugated Web Girders

Shear Buckling Behavior

Since shear forces are primarily resisted by the corrugated web, the primary failure mode of such bridges is shear buckling. The stability of corrugated steel webs depends on the geometry of the corrugations and their ability to resist applied loads without excessive deformation.

Types of Buckling Modes

- Local Buckling: Occurs when individual folds of the corrugated web buckle under shear forces. This mode is critical for deep folds, where the web acts as a series of mutually supporting flat panels.

- Global Buckling: Involves the buckling of the entire corrugated steel web, affecting shallow folds more significantly.

- Interactive Buckling: A combination of local and global buckling modes, making it the most complex failure mode to predict. Research indicates that interactive shear buckling governs failure in most corrugated web applications.

Torsional Behavior

Compared to conventional prestressed concrete (PC) box girders, corrugated steel webs have lower out-of-plane stiffness, making them more prone to cross-sectional distortion. This effect is particularly important in curved or skewed bridges, where diaphragms must be provided at suitable intervals to control torsional distortion.

Advantages of Corrugated Webs

The introduction of corrugated webs in bridge girders has led to numerous advantages, making them increasingly popular in countries such as Sweden, France, Germany, and Japan. Some key benefits include:

- Weight Reduction: Corrugated steel webs are significantly lighter than concrete webs, leading to reduced seismic forces and smaller substructures, thereby lowering overall construction costs.

- Enhanced Shear Resistance: Compared to flat steel webs, corrugated webs have higher out-of-plane stiffness and shear buckling resistance, even without additional stiffeners, which reduces material and labor costs.

- Cost Efficiency: Bridges with corrugated webs are approximately 20% lighter and require 20% less prestressing strands than those with concrete webs, making them more economical for spans exceeding 50m.

- Hybrid Construction Potential: Corrugated web girders can be combined with steel box girders, enabling long-span hybrid bridges.

- Environmental Benefits: Bridges with corrugated webs emit approximately 20% less carbon dioxide than traditional steel or concrete bridges, making them an eco-friendly alternative.

- Material Efficiency: Concrete primarily resists bending moments, while steel effectively carries shear forces, leading to an optimized material distribution.

- Application in Long-Span Bridges: Corrugated steel web box girder bridges are particularly competitive for spans exceeding 100m.

- Aesthetic Appeal: The unique visual appearance of corrugated webs enhances the aesthetics of bridge structures.

Conclusion

Corrugated steel webs effectively combine the advantages of steel and concrete, reducing the self-weight of main girders while enabling longer spans and lowering construction costs. Although this technology is relatively new, with fewer than ten bridges currently utilizing corrugated web girders, the structural and economic benefits make it a promising solution for future bridge projects. With ongoing research and development, the use of corrugated steel web girders is expected to grow, offering a sustainable and efficient alternative for modern bridge construction.