Bridges are essential elements in modern transportation infrastructure, providing crucial connections over rivers, roads, and other natural or man-made barriers. However, the safety, stability, and longevity of these bridges depend heavily on their design, which needs to account for a wide range of forces and stresses that will act on them throughout their lifespan. These forces, or “loads,” come in many forms, and understanding each type of load is essential to ensuring the bridge can withstand the pressures of daily traffic, environmental factors, and natural events. This article will explore the various types of loads that must be considered in the design of bridge structures.

I. Types of Loads for Bridge Design

1. Dead Load

Dead load refers to the constant, unchanging weight of the bridge itself. This includes the weight of all its structural components, such as the deck slab, railings, parapets, stiffeners, and utilities. Dead load is typically the first design load to be calculated since it is the most predictable and permanent force acting on the bridge. As the foundation and structure remain constant over time, this load forms the baseline for calculating other dynamic loads.

2. Live Load

Live load is the moving load that changes over time, most often associated with vehicles, pedestrians, and other transient factors that cross the bridge. Live loads are harder to predict, as they vary based on traffic volume, types of vehicles, and movement patterns. To ensure a bridge can handle a wide range of traffic, the Indian Roads Congress (IRC) has defined specific categories of live loads, including:

- IRC Class AA Loading: Applied to heavy-duty bridges, such as those in highways or industrial areas, where both tracked and wheeled vehicles are considered.

- IRC Class A Loading: Standard live load for permanent bridges, ensuring that the bridge can handle typical traffic.

- IRC Class B Loading: Light loading applied in temporary bridges, such as timber bridges, often found in low-traffic areas.

3. Impact Load

Impact load arises from the sudden change in force when vehicles move over the bridge, causing periodic fluctuations in the live load as one wheel of the vehicle moves to the next. The bridge must be designed to handle these sudden forces, known as impact loads, which can be amplified by factors such as vehicle weight, speed, and span length. The impact factor is used to adjust for these effects, and different IRC categories have specific formulas to calculate the impact load based on vehicle type and span.

For example:

- For IRC Class AA loading, a tracked vehicle might have an impact factor as high as 25% for shorter spans, while a wheeled vehicle would have a consistent impact factor up to 9 meters.

- For IRC Class A and B loadings, simpler formulas are used to adjust for impact based on the bridge type and span length.

4. Wind Load

Wind load is particularly significant in areas where strong winds are common. For short-span bridges, wind load is often negligible, but for medium and long-span bridges, it can affect both the substructure and superstructure of the bridge. The forces caused by wind pressure must be considered to prevent structural failure or excessive sway, especially for long-span bridges or those built in open, wind-prone areas.

5. Longitudinal Forces

Longitudinal forces are caused by the braking or accelerating of vehicles on the bridge. When vehicles come to a sudden stop or rapidly accelerate, the bridge structure experiences additional forces, especially on the substructure. The IRC recommends that 20% of the live load be considered as longitudinal forces in bridge design to account for these dynamic effects.

6. Centrifugal Forces

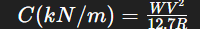

In bridges built on curves, centrifugal forces act on the structure as vehicles move around the curve. These forces are caused by the vehicle’s motion along a curved path, creating additional stress on the bridge. The centrifugal force can be calculated using the formula:

where W is the live load, V is the design speed, and R is the radius of the curve. These forces must be carefully accounted for in the design of curved bridges.

7. Buoyancy Effect

For bridges submerged in deep water, buoyancy effects must be considered in the design of the substructure. Buoyancy can cause the bridge components to experience an upward force, especially if parts of the bridge are under water. However, for bridges with shallow submergence, this effect is generally negligible and can be ignored in the design process.

8. Forces Due to Water Current

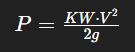

When bridges are constructed across rivers or other bodies of water, the substructure submerged in the water will experience horizontal forces due to water currents. These forces are strongest at the water’s surface and decrease towards the bed level. The pressure from water currents is given by the formula:

where P is the pressure, K is a constant, W is the unit weight of water, V is the water current velocity, and g is the acceleration due to gravity. This force must be taken into account in the design of submerged portions of the bridge to ensure their stability.

9. Thermal Stresses

Temperature variations, whether extreme heat or cold, can cause thermal expansion or contraction of bridge materials. These changes induce tensile stresses, particularly at bearings and deck joints. To mitigate thermal stresses, additional steel reinforcement is often provided, and expansion joints are incorporated into the design. This ensures that the bridge can accommodate temperature-induced movements without cracking or failing.

10. Seismic Loads

In earthquake-prone areas, seismic loads must be factored into the design of the bridge. Earthquakes generate both vertical and horizontal forces that can shake or displace the bridge structure. The magnitude of these forces is influenced by the self-weight of the structure: heavier bridges experience more significant seismic forces. Proper seismic design ensures that the bridge can resist the forces generated by earthquakes without collapsing or sustaining significant damage.

11. Deformation and Horizontal Effects

Deformations in bridge materials can occur over time due to factors such as material creep or shrinkage of concrete. Additionally, external factors like temperature changes, braking of vehicles, and seismic activity can generate horizontal forces that impact the bridge. These forces must be considered to ensure the bridge remains stable and functional throughout its life.

12. Erection Stresses

During the construction phase, stresses are induced by the construction equipment used to assemble the bridge. These stresses must be accounted for in the design, and suitable supports must be provided to prevent deformation or damage to the structure during construction.

Conclusion

The design of a bridge requires careful consideration of a wide range of loads and forces that will act upon the structure throughout its life. These loads include dead load, live load, impact load, wind load, longitudinal forces, centrifugal forces, and more. Each type of load, from the weight of the bridge itself to the impact of environmental forces like wind and water, plays a critical role in ensuring the safety and durability of the bridge. By properly accounting for these factors in the design process, engineers can create bridges that will stand the test of time, providing safe and reliable passage for vehicles and pedestrians alike.