Concrete structures are vital components of our infrastructure, supporting buildings, bridges, roads, and more. However, concrete isn’t immune to deterioration over time. Regular inspections are crucial for identifying potential issues early, allowing for timely repairs that extend the lifespan and ensure the continued performance of these critical assets. This article outlines a comprehensive visual inspection checklist designed to help inspectors conduct thorough assessments, focusing on key areas that impact concrete durability. While this checklist provides a solid foundation, remember it can be adapted and expanded based on specific project requirements and environmental factors.

I. Introduction: Concrete Inspection & Durability

The longevity of any concrete structure hinges on proactive maintenance and diligent inspection. A well-executed inspection process allows us to identify subtle signs of degradation before they escalate into costly repairs or structural failures. Checklists, like the one detailed below, serve as invaluable tools for ensuring a systematic and inclusive approach to these assessments. While this checklist covers essential elements, it’s important to recognize that other factors influencing concrete performance may warrant further investigation beyond what’s listed here.

II. Visual Inspection – A Key Component

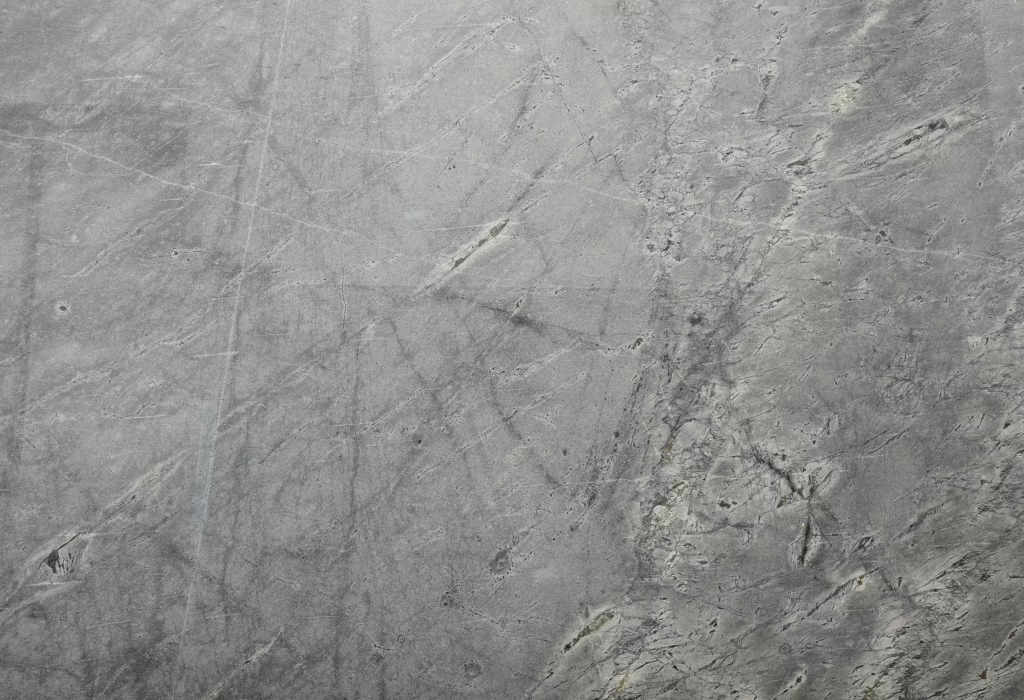

Visual inspection is the cornerstone of concrete assessment. It involves a careful examination of the concrete surface to identify and document various conditions that can arise throughout its lifespan. This process isn’t just about identifying existing problems; it’s about detecting early warning signs, facilitating timely repairs before more extensive (and expensive) replacements become necessary. A proactive approach to visual inspection is an investment in the long-term health of concrete structures.

III. Concrete Inspection Checklist: A Detailed Breakdown

This checklist is organized into categories reflecting different aspects of a concrete structure’s condition and environment. Each section provides specific items to examine, ensuring a comprehensive assessment.

- A. Structure Identification & Background Information: The inspection should begin with establishing the context.

- Description of Structure Details: Record the name, location, type (e.g., bridge deck, foundation wall), and size of the structure being inspected.

- Project History: Gather information about the owner, project engineer, contractor involved in construction, and the date of completion. This historical data can provide valuable insights into design considerations and potential past issues.

- Documentation (Photographs): Capture both general views of the entire structure and detailed close-up images of any areas exhibiting signs of distress. These photographs serve as a visual record for future comparisons and documentation purposes.

- Site Mapping: Create a map illustrating the orientation of the structure, noting sunny and shady areas, and identifying regions with good or poor drainage.

- B. Environmental & Loading Conditions: Understanding the forces acting on the concrete is crucial for interpreting observed conditions.

- Environmental Exposure: Assess exposure to:

- Arid climates (leading to drying shrinkage)

- Subtropical environments (with fluctuating temperatures and humidity)

- Marine environments (saltwater corrosion)

- Freshwater environments (potential for algae growth and freeze-thaw damage)

- Industrial environments (exposure to corrosive chemicals)

- Physical Loading: Consider the impact of:

- Freeze-Thaw Cycles & Wetting/Drying (leading to cracking and spalling)

- Chemical Attack (sulfates, acids, bases, chlorides, gases – causing corrosion and degradation)

- Abrasion, Erosion, Cavitation, Impact (physical wear and tear)

- Electrical Conductivity (relevant for structures with electrical systems)

- Deicing Chemicals (chloride ions accelerate corrosion of reinforcing steel)

- Heat Sources (thermal expansion and contraction stresses)

- Environmental Exposure: Assess exposure to:

- C. Drainage Assessment: Proper drainage is essential to prevent water infiltration, a major contributor to concrete deterioration.

- Inspect flashing joints, sealants, weep holes, and the contour elevation of drains for functionality and integrity.

- D. Loading Conditions Analysis: Evaluate the types of loads the structure experiences:

- Dead Load (weight of the structure itself)

- Live Load (variable weight from occupants or traffic)

- Impact Load (sudden, short-duration forces)

- Vibration (repeated oscillations)

- Traffic Load (for roadways and bridges)

- Seismic Load (forces during earthquakes)

- Other Loads (specific to the structure’s function)

- E. Foundation/Soil Conditions: The soil supporting the concrete can significantly impact its performance.

- Look for signs of:

- Expansive Soil (swelling and shrinking with moisture changes, causing cracking)

- Compressible Soil (settlement leading to structural distress)

- Evidence of Pumping (voids beneath the slab caused by water movement)

- Look for signs of:

- F. Distress Indicators – Visual Signs of Problems: These are the telltale signs that something isn’t right.

- Cracking (Note location, frequency, width, pattern, and any evidence of leaching)

- Staining (indicates potential chemical exposure or water infiltration)

- Surface Deposits & Exudations (can indicate moisture problems or chemical reactions)

- Leaking (obvious sign of water penetration)

- G. Structural Alignment Assessment: Observe the overall geometry of the structure.

- Look for signs of: Settlement, Deflection, Expansion/Contraction.

- H. Concrete Surface Condition (Overall): A general assessment of the concrete’s appearance.

- Categorize as: Good, Satisfactory, or Poor.

- I. Formed & Finished Surfaces Evaluation: Assess the quality of the initial construction.

- Surface Quality: Smoothness

- Defects: Bugholes (surface air voids), Sand Streaks, Honeycomb (voids within the concrete), Soft Areas, Cold Joints (poor bonding between pours), Staining

- J. Specific Defects – Detailed Inspection: A closer look at common issues.

- Scaling (Type, Area, Depth)

- Spalls & Popouts (Number, Size, Depth, Type)

- Exposed Reinforcement (Corrosion)

- Curling/Warping

- Erosion (Abrasion, Cavitation)

- K. Previous Repairs: Evaluate the effectiveness of any past repair work.

- L. Protective Systems & Sealers: If protective coatings or sealers are present, assess their condition.

- Surface Coatings: Type, Thickness, Bond to Concrete, Condition

- Penetrating Sealers: Type, Effectiveness, Discoloration

IV. Conclusion

A thorough visual inspection is a cornerstone of proactive concrete management. By systematically utilizing this checklist and adapting it to the specific characteristics of each structure, inspectors can identify potential problems early on, enabling timely interventions that extend the lifespan and ensure the continued performance of these vital assets. Remember, consistent monitoring and documentation are key to maintaining the integrity of our concrete infrastructure for years to come.