The standard consistency of cement refers to the water content at which the Vicat plunger penetrates the cement paste to a depth of 5 to 7 mm from the bottom of the Vicat mould. This test is crucial in determining the amount of water required to produce a cement paste that will be used for various other tests, such as initial and final setting time.

Understanding the standard consistency ensures uniformity in testing conditions and helps in evaluating the performance of cement under standardized conditions.

Apparatus Required

To determine the standard consistency of cement, the following apparatus is used:

1. Vicat Apparatus

The Vicat apparatus consists of a rigid frame with a movable rod that can hold interchangeable attachments. These include:

- A needle for determining the initial setting time

- A needle for determining the final setting time

- A plunger for determining the standard consistency

2. Needles and Plunger

- Initial Setting Time Needle: Flat-ended needle with a cross-sectional area of 1 mm².

- Final Setting Time Needle: Circular needle with a cross-sectional area of 1 mm², fitted with a hollow metal attachment so that only the tip projects.

- Plunger for Standard Consistency: Made of polished brass, 10 ± 0.05 mm in diameter, with a flat lower end and a projection on the upper end for attachment to the rod.

3. Movable Rod with Indicator

The movable rod has an indicator that moves along a graduated scale. Some models include a dashpot mechanism to allow smooth lowering of the rod.

4. Graduated Scale

The scale is 40 mm long with 1 mm divisions, allowing precise measurement of the penetration depth.

5. Vicat Mould

Two types of moulds are used:

- Single Mould: Frustum of a cone with internal dimensions:

- Top diameter: 60 ± 0.5 mm

- Bottom diameter: 70 ± 0.5 mm

- Height: 40 ± 0.5 mm

- Split Type Mould: A split ring with internal diameter 80 ± 0.1 mm and height 40 ± 0.5 mm, clamped together and placed on a non-porous base plate.

Procedure for Determining Standard Consistency

Preparation of Apparatus

- Place the Vicat apparatus on a level, stable surface.

- If using a dashpot model, raise the bearing movable rod to its highest position and secure it with a pin.

- Unscrew the dashpot cap, half-fill it with suitable oil, and screw the cap back on.

- Move the plunger several times to ensure smooth operation.

Attachment of Plunger

- Fix the standard consistency plunger to the movable rod.

- Operate the plunger a few times to ensure free movement.

Cement Paste Preparation

- Take 400 grams of cement and pour it into a mixing pan.

- Measure a known quantity of water (start with approximately 25–30% of the weight of cement).

- Begin a stopwatch when adding water to the cement.

- Mix thoroughly for 3 to 5 minutes to obtain a uniform paste.

Filling the Mould

- Place the Vicat mould on a non-porous base plate.

- Fill the mould completely with the cement paste.

- Gently tap or shake the mould to remove air bubbles.

- Level the top surface of the paste with a trowel.

Testing with Plunger

- Position the filled mould under the plunger.

- Lower the plunger gently until it touches the surface of the paste.

- Release the plunger quickly and observe how far it sinks into the paste.

- In models with a dashpot, follow the specific steps for releasing the plunger after securing the mould in place.

Trials

- Repeat the process with varying percentages of water until the plunger penetrates between 5 and 7 mm.

- Record the percentage of water used in each trial.

Observations and Calculations

Record the following data during the test:

| Sl. No. | Quantity of Water Added (ml) | Depth of Penetration (mm) |

Given:

- Weight of cement taken = ______ g

- Initial percentage of water added = ______

- Quantity of water added = ______ ml

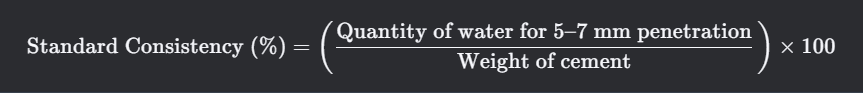

Formula:

Important Notes During Testing

To ensure accurate results, follow these key guidelines:

- The gauging time should be between 3 and 5 minutes.

- Conduct the test at a room temperature of 27°C ± 2°C.

- Avoid any vibrations on the working table during the test.

- Clean the plunger thoroughly before each trial to prevent contamination.

Results

After completing the trials and calculations, the standard consistency of the cement sample is determined and expressed as a percentage of water by weight of dry cement.

Result:

Percentage of water content for standard consistency = ___%