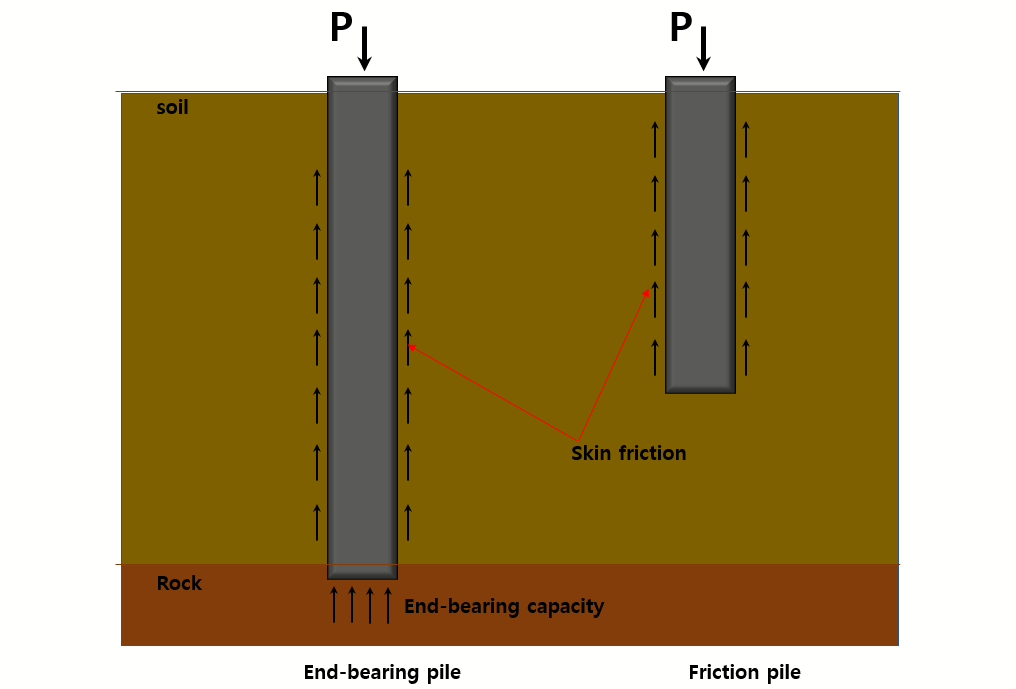

Pile foundations play a crucial role in construction by transferring heavy, concentrated loads from structures to the underlying competent soil or rock layers. Given the nature of piling work, which involves the use of heavy-duty machinery and complex operations, adhering to stringent safety protocols is essential to protect workers and ensure a smooth construction process. This article covers the key safety measures and best practices that must be followed during piling operations.

Safety Program

Successful piling operations begin with a well-structured safety program. A qualified and competent foreman should oversee all activities at the site, ensuring that safety arrangements are strictly maintained. When work extends into the night, adequate lighting of at least 100 lux intensity is mandatory to provide safe visibility.

Operators of cranes and hoisting appliances must demonstrate competence and receive approval from the engineer-in-charge. Importantly, personnel under 21 years old should not operate hoisting machines, scaffolding, or give signals to operators. Deep foundation works involving compressed air require special precautions to protect workers from serious risks such as compressed air disease and other health hazards.

Piling Rig Safety

The piling rig is the heart of the operation and must be handled with utmost care. Pile drivers should be installed far enough from electric conductors to avoid accidental contact. When two pile drivers are installed at the same site, they must be spaced at least the length of the longest rig leg apart to prevent interference or accidents.

The rig’s structural integrity must be assured for all expected loads, including live, dead, and wind forces. If any doubts arise, the structural foreman must conduct tests before use. No piling equipment should be put into operation without thorough inspection and confirmation of safety.

Pile drivers must rest on secure foundations such as heavy timber sills or concrete beds. To maintain stability during adverse weather or seismic activity, the rig should be anchored with at least four guy wires. Competent engineers should inspect the equipment regularly, at intervals not exceeding three months, to identify any wear or defects.

Before each shift, the foreman must check pile lines, pulley blocks, and other critical parts for damage or wear. Repairs to mechanical slings, sheaves, hoses, or other components must only be performed by qualified personnel, with the foreman overseeing the process. Air and steam equipment should never be repaired while under pressure or in operation.

Hoisting ropes must be made of galvanized steel for durability, and steam or air lines should have easily accessible shut-off valves. Air and steam hammer hoses must be securely fastened to prevent whipping if disconnected. When not in use, hammers should be lowered and held securely in place.

Safe working loads for hoisting equipment—including chains, hooks, shackles, and pulleys—must be clearly identified, and regular testing should verify that operational loads do not exceed half of the tested safe load. Additionally, dangerous parts of the machinery like motor gears and electrical wiring require appropriate safeguards to prevent injury.

Workers handling electrical installations on energized equipment must wear insulating gloves and stand on insulating mats. When loads need to be inclined, they must be properly counterbalanced and secured to prevent slipping. Precautions are also necessary to prevent pile drivers from overturning if a wheel fails and to avoid hammer misses during operation.

Long piles and heavy sheet piling should be firmly secured to prevent accidental falls during work. If steam boilers power the equipment, strict compliance with boiler safety standards is essential, including adjusting safety valves to 7 N/cm² above working pressure.

Safety Precautions During Operation

While operating pile drivers, all personnel nearby must wear helmets that meet accepted safety standards to protect against falling objects or other hazards.

Piles should be prepared at a safe distance—at least twice the length of the longest pile—from the pile driver to prevent accidental impacts. When hoisting piles, they must be slung carefully to avoid swinging or whipping, and a hand rope should be attached for controlled movement.

Workers guiding piles into position should never place their hands or arms between the pile and guide rails; instead, ropes should be used for guidance. To protect the pile during lifting, iron rings or caps should cover the driving end to avoid damage.

When driving creosoted wood piles, workers must take precautions against skin and eye injuries caused by creosote splashes. Finally, no air or steam should be released until all personnel are at a safe distance from the operation area.

Frequently Asked Questions (FAQs)

Q: What is the safe distance between two pile drivers?

A: Two pile drivers erected at the same site should be spaced at least the length of the longest leg in either rig apart to ensure safety.

Q: What safety protocols should be checked during piling?

A: Key safety checks include:

- Display of OSHA notices and safety posters

- Up-to-date OSHA records

- Safe storage of materials

- Proper housekeeping on site

- Availability and condition of fire extinguishers

- Equipped first-aid kits

- Good safety practices in work habits

- Foremen providing proper safety instruction to workers

Conclusion

Piling work involves numerous risks due to the heavy machinery and complex processes involved. Implementing comprehensive safety programs, ensuring rig integrity, and following operational precautions protect workers and help avoid costly accidents. Strict adherence to the protocols outlined here is vital for maintaining a safe and efficient piling operation.