Tiles are versatile, durable, and aesthetically pleasing materials widely used in construction for flooring, walls, and countertops. They come in various forms—ceramic, porcelain, natural stone, glass, metal, terrazzo, and baked clay—each offering unique properties such as color, texture, hardness, and resistance to moisture and wear.

While aesthetics play a crucial role in tile selection, the mechanical properties of tiles—especially their strength—are equally important. One of the key indicators of a tile’s suitability for specific applications is its transverse strength. This article delves into the concept of transverse strength testing of floor tiles, explaining the methodology, equipment, and significance of both dry and wet tests.

Understanding Transverse Strength

Transverse strength, also known as modulus of rupture (MOR), refers to a material’s ability to resist bending or breaking under load applied perpendicular to its longitudinal axis. In the context of floor tiles, it measures how much pressure a tile can withstand before fracturing when supported at two points and loaded at a third central point.

This test helps determine whether a particular tile is suitable for light-duty residential use or heavy-duty commercial applications like shopping malls, airports, or industrial floors.

Two types of transverse strength tests are commonly conducted:

- Dry Test: Evaluates the strength of air-dried tiles.

- Wet Test: Assesses the strength after the tiles have been soaked in water, simulating real-world conditions where moisture may affect performance.

The results from these tests provide critical data that guide engineers, architects, and builders in selecting appropriate tiles for different environments.

Apparatus Used in Transverse Strength Testing

The transverse strength test is performed using a specialized tile testing machine, which consists of the following components:

1. Frame and Lever System

- Constructed from angle iron for durability.

- Features a double lever system with ball bearings for smooth operation.

- The lower lever carries a counterbalanced weight and a receiving pan for collecting lead shots.

2. Loading Mechanism

- Lead shots flow through a valve-controlled pipe into the receiving pan, applying gradual pressure on the specimen.

- The loading rate is controlled at 45–55 kg/min.

- An L-shaped plate automatically stops the flow of lead shots upon specimen failure.

3. Support and Loading Rollers

- Three 40 mm diameter rollers are used:

- Two support rollers mounted on self-aligning bearings.

- One loading roller connected to the upper lever via vertical rods.

- Center distance between supports is adjustable to accommodate different tile lengths (250 mm for 320 mm tiles and 270 mm for 345 mm tiles).

4. Safety and Measurement Components

- A stopper limits the movement of the lower lever after failure.

- The failure load is calculated by multiplying the collected lead shot weight by 12.

Tile Specimen Preparation

To ensure accurate and consistent results, proper preparation of tile specimens is essential:

- Number of Samples: Six tiles for dry strength testing and six for wet strength testing.

- Conditioning:

- Dry Test: Tiles should be air-dried.

- Wet Test: Tiles must be immersed in water for 24 hours and then wiped dry before testing.

Each tile is inspected for cracks or defects prior to testing to avoid misleading results.

Machine Operation Steps

Before starting the test, the machine must be calibrated and adjusted accordingly:

- Mount the Counterbalance Weight on the screw attached to the lower lever.

- Adjust the Loading Yoke and Roller based on the thickness of the tile.

- Balance the Lower Lever using the counterweight and lock it in place.

- Place the Tile Specimen on the bearing rollers.

- Start Loading by opening the valve to allow lead shots to flow into the receiving pan.

- Monitor Load Application until the tile breaks.

- Automatic Shut-off occurs when the L-shaped plate strikes the valve shutter.

- Collect and Weigh Lead Shots to calculate the failure load.

Test Procedures

A. Dry Test Procedure

- Place the air-dried tile horizontally on the bearers with its wearing surface facing up.

- Insert 3 mm thick plywood packing strips (25 mm wide) between the tile and the rollers to prevent localized crushing.

- Apply the load gradually and uniformly, starting from zero, at a rate not exceeding 200 kg per meter width per minute.

- Continue loading until the tile fractures.

- Record the breaking load.

- Repeat the procedure for all six specimens and compute the average.

B. Wet Test Procedure

- Immerse the tile specimens in water for 24 hours to simulate wet conditions.

- Remove them and wipe off excess water.

- Conduct the same test procedure as in the dry test.

- Compare the wet test results with the dry test values to assess the effect of moisture on tile strength.

Results and Calculations

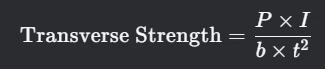

After conducting the tests, the transverse strength is calculated using the formula:

Where:

- P = Breaking load (in Newtons)

- I = Span between supports (in mm)

- b = Width of the tile (in mm)

- t = Thickness of the tile (in mm)

Designated Spans for Different Tile Sizes

| Tile Size (mm) | Span Between Supports (mm) |

|---|---|

| 200 x 200 | 150 |

| 250 x 250 | 200 |

| 300 x 300 | 250 |

| 400 x 400 | 300 |

These standardized spans ensure consistency in testing across different tile dimensions.

Conclusion

Transverse strength testing is an indispensable part of quality control in the tile manufacturing and application process. By subjecting tiles to both dry and wet tests, manufacturers and users can evaluate the structural integrity and durability of tiles under varying conditions.

The use of a well-calibrated tile testing machine, along with precise procedures and calculations, ensures reliable results that help in making informed decisions about tile usage in residential, commercial, and industrial settings.

Understanding and applying the principles of transverse strength testing not only enhances safety but also contributes to long-lasting, efficient, and cost-effective building solutions.